Managing our environment responsibly

To make mining work we need to minimize our environmental footprint by using natural resources efficiently, by preventing or limiting emissions and by reducing waste. Each of our operations is responsible to identify, analyze and manage environmental risks and to work in a transparent manner with local stakeholders, building a foundation of trust and cooperation.

2019 Key Highlights

- 520,832 tonnes (CO2 equivalent) of GHG Scope 1 & 2 emissions produced by our operations

- 0.027 CO2 equivalent per tonne of ore treated

- 17.41 Mm3 water released to our environment from all our mining operations

- 0 number of significant environmental incidents

- 68% of our electricity is from renewable sources

- 9.532 Mm3 of freshwater withdrawn from all sources

- 13.37M tonnes of tailings generated

Energy and Climate Change

Agnico Eagle uses a variety of energy sources including electricity, diesel, gasoline, propane and natural gas for our operations. Electricity and diesel are the most important energy sources. Overall, 68% of the electricity is from non-carbon emitting sources, primarily hydroelectricity. Our annual electricity consumption increased by 7.8% to 1,202 Gigawatt hours (GWh) in 2019. This increase is largely attributed to the opening of the Meliadine Mine in Nunavut.

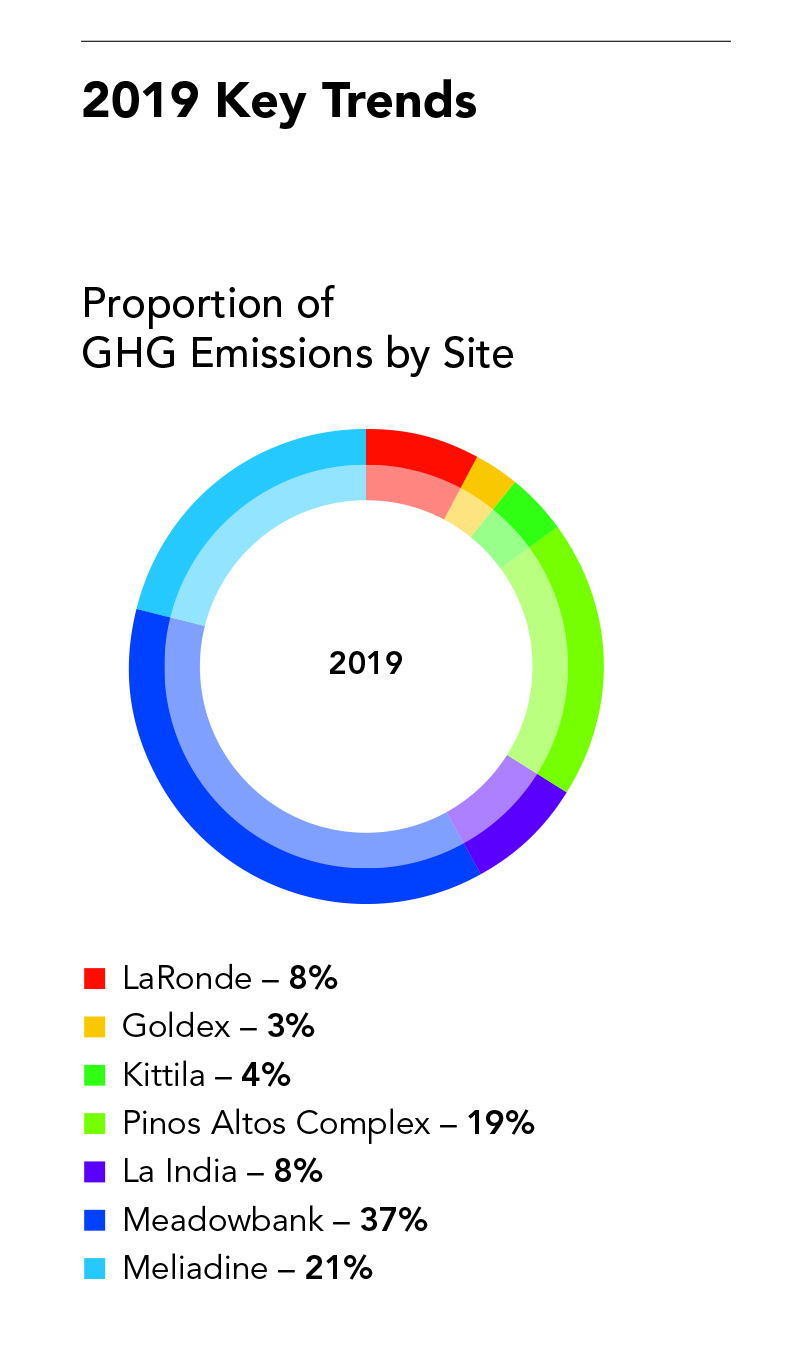

Greenhouse Gas Emissions

Total direct and indirect GHG emissions were 520,832 tonnes of CO2 equivalent in 2019, an increase of 27% from 2018. This is attributed to the opening of the Meliadine mine, which accounts for 21% of emissions and the increased energy intensity. Nunavut operations account for 58% of Agnico Eagle’s total GHG production.

Our average GHG emissions intensity (tonnes of CO2 equivalent per tonne of ore processed) for all of our operating mines increased by 30% from 0.021 in 2018 to 0.027 in 2019. This is attributed to the addition of our Meliadine operations, the beginning of ore hauling between the Amaruq deposit and the mill at Meadowbank, and less throughput at our operations in Mexico and Finland. LaRonde and Goldex reduced their GHG emission intensity by 3% and 6%, respectively. Higher throughput at both mines and the increased utilization of the Rail Veyor at Goldex improved the operations’ efficiencies, reducing the energy use per tonne of material mined.

We understand that we are at a critical juncture in the climate crisis and we know that the status quo cannot be maintained. We believe in the importance of making both short- and long-term goals to tackle our emission reduction objectives. Currently, all our sites are implementing GHG reduction initiatives and in 2020, we will prepare our first Climate Action Plan in line with the recommendations of TCFD.

In 2019, several energy reduction initiatives were implemented to optimize the growing energy demands of our Nunavut operations, including the insulation of remote buildings, the installation of a composter to minimize the use of the incinerator, and a campaign to encourage employees at camp to reduce their energy consumption.

Increasing the proportion of non-carbon emitting electricity sources is important for Agnico Eagle to meet our long-term energy and greenhouse gas (GHG) objectives. Agnico Eagle believes that by working closely with local businesses, communities, and governments we can find solutions that not only reduce our carbon footprint, but also provide emission reductions for the region, in addition to creating economic benefits. This is really what makes mining work, and this is why we are pursuing a wind farm project at the Meliadine Mine and continue to support initiatives for infrastructure development that would bring hydroelectricity and fibre-optic connectivity from Northern Manitoba to the Kivalliq region. In Mexico, we are working with stakeholders to gain approval for the construction of a power line that would bring electrical power to supply La India mine and reduce our fuel consumption.

Water Management

In 2019, the total fresh water withdrawn by Agnico Eagle from all sources was 9.532 million m3 (Mm3), which is a 30% increase from 7.340 Mm3 in 2018. The increase can be attributed to the commencement of production at Meliadine, the start of the in-pit tailings deposition at Meadowbank that impacted our ability to recycle process water, and some adjustments at Goldex in how data is reported.

Our total water use was 0.49 m3 per tonne of ore processed, up from 0.37 m3 per tonne in 2018, which represents a 33% increase as seen in Figure 11. This is attributed to the increase of freshwater use as mentioned above, and lower throughput at Meadowbank, our Mexico operations, and Kittila mine.

In 2019, our water discharge to the environment was 17.4 Mm3 an increase of 78% from the previous year. This increase can be attributed to the dewatering needed for operation of the Whale Tail pit (Meadowbank Complex) and the exceptionally high precipitation in Nunavut and Abitibi.

During the year, we also drafted a corporate standard (CS) for water management, that lays out industry-leading practices for integrated water management. This will be implemented in 2020 across the Company.

Tailings and Waste Management

Agnico Eagle has developed stringent guidelines that govern management of our Tailings Storage Facilities (TSFs) to ensure that all infrastructures, whether operating or closed, meet or exceed regulatory requirements and industry standard practices or guidelines.

In 2019, we implemented additional measures to adhere to the updates in the latest version of MAC’s (TSM) Tailings Management Protocol. Governance changes included in the updated MAC Tailings Guide will ultimately have a significant and positive impact on the risk profile of our infrastructure at all phases of the mine life-cycle – through design, construction, operation and closure.

In addition to TSF governance, Agnico Eagle has embarked on updating our risk assessment of all critical infrastructure. This work was initiated in 2019 and will continue in 2020, with the aim of achieving a more systematic, consistent and quantitative assessment of the risk profile of different critical infrastructure.

In 2019, the total ore tonnage processed through our milling and heap leach facilities was approximately 19.57 million tonnes (Mt), a decrease of 3.2% compared to 2018. The tonnage of ore placed on heap leach facilities was approximately 6.5 Mt, as compared to 7.8 Mt in 2018. This decrease is attributed to the reduction of pit tonnage at Pinos Altos, which is the main source of heap leach ore at this mine. The total amount of tailings produced by the milling operations was approximately 13.1 Mt, as compared to 12.4 Mt in 2018, an increase of 6%. This increase can be attributed to the start of production at Meliadine. It should be noted that Meliadine is using filtered tailings, which is considered best available technology for the region. This approach, although higher cost during operations, facilitates an easier and more robust closure at the end of operations.

To learn more about our environment performance, initiatives and priorities, click here.

To read about some of our environment related stories, click here.